Sodium Ion Battery

Classification:

Products

Key words: Sodium Ion Battery

Product Description

Performance Advantages

Driven by global carbon neutrality goals, sodium-ion batteries have emerged as a prominent player in the energy storage sector due to their abundant resources, low cost, and exceptional safety. Sodium, with a crustal abundance of 2.75% (far exceeding lithium’s 0.0065%), is widely distributed globally, effectively mitigating risks associated with overdependence on lithium resources. Key advantages include a cost approximately half that of lithium-ion batteries, a cycle life of up to 3,000 cycles (compared to 300 cycles for lead-acid batteries), and stable operation in extreme temperatures ranging from -40°C to 80°C, making them ideal for energy storage in frigid regions and winter electric vehicle charging. Additionally, sodium-ion batteries utilize aluminum foil for both cathode and anode current collectors, further reducing material costs. Haosheng New Energy’s achievements include collaborative innovation with Southwest University through a joint sodium-ion battery materials laboratory, extensive industry validation via sample testing with leading companies like Vision Technology, Lishen New Energy, and Guoxuan High-Tech, three generations of technological breakthroughs in cathode materials (with the latest polyanionic system achieving advanced performance), and accelerated industrialization with an annual production capacity of 20,000 tons of sodium-ion battery materials across a 183-acre facility.

Product Specifications

1. Composite Sodium Iron Phosphate (NFPP)

a. High Specific Capacity: 110 mAh/g (industry-leading).

b. Long Cycle Stability: 80% capacity retention after 3,000 cycles (half-cell).

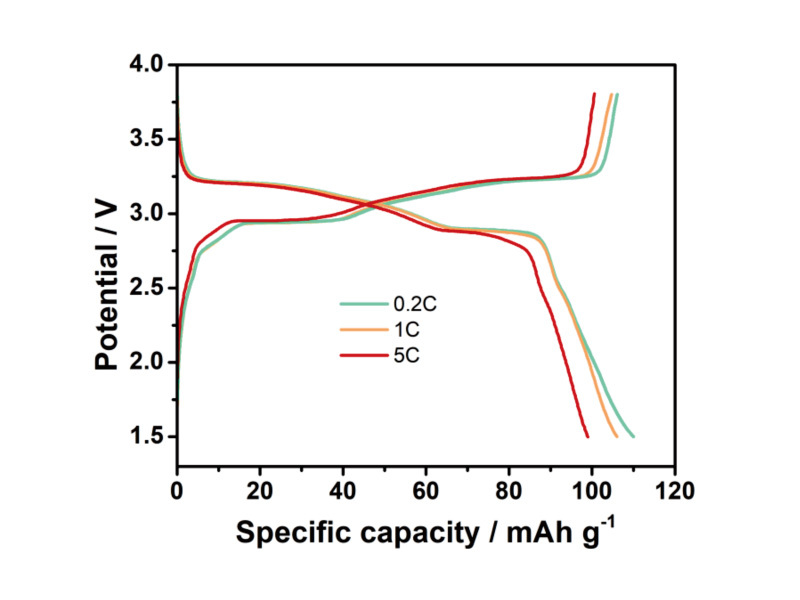

c. High Rate Performance: 90% capacity retention at 5C.

d. Low pH Value: pH 9.3, ensuring excellent processability.

e. Cost Advantage: Strict cost control for significant cell-level competitiveness.

2. Sodium-Compensated NFPP (S-NFPP)

a. Exclusive Sodium-Supplement Coating: Enhances initial charge capacity without compromising electrochemical or processing performance.

b. Energy Density: Enables full-cell initial Coulombic efficiency exceeding 95%.

c. Cycle Performance: Forms a sodium slow-release layer on the anode to improve cycling stability.

d. pH Reduction: Further lowers material pH to 9.3.

e. Cost Advantage: Maintains cell-level cost leadership.

3. Sodium Compensation Agent (NaCrO₂)

a. High Sodium Content: Maximizes active material utilization for enhanced energy storage.

b. Gas-Free Design: Ensures structural stability and safety.

c. Broad Compatibility: Delivers performance improvements across diverse sodium battery systems.

Previous Page

Next Page

Related Products

Product Consulting